IT Environmental Stewardship: The Edgeium Difference

Environmental sustainability in the IT sector is more critical than ever. At Edgeium, we are committed to reducing e-waste and promoting a circular...

Thomas Edison put it this way, “Waste is worse than loss …. Every person who lays claim to ability will keep the question of waste before him constantly. The scope of thrift is limitless.” We'll tell you how we improved the network hardware lifecycle of one of our customers.

We recently worked with an IT manager who took this idea seriously. His department lacked a comprehensive view of maintenance coverage for all of its Cisco assets. Wasteful spending had emerged as a major issue, draining time and budget that were needed elsewhere.

When we sat down with the manager the problem became clear. Throughout the growing company’s many locations were dozens of maintenance contracts, each with different termination dates. While some worksites needed expansion, other sites had been downsized or divested. The company was put in a position of paying for coverage on gear it no longer owned. The struggle to get a handle on network assets multiplied with each passing year.

The company’s previous approach had been to engage the OEM and renew coverage based on the most recent renewal. In the wake of growth, this approach no longer worked. With so many assets in disperse locations, maintenance costs were out-of-control. Cisco’s End-of-Sale and End-of-Support announcements compounded the problem, further squeezing CapEx and OpEx budgets.

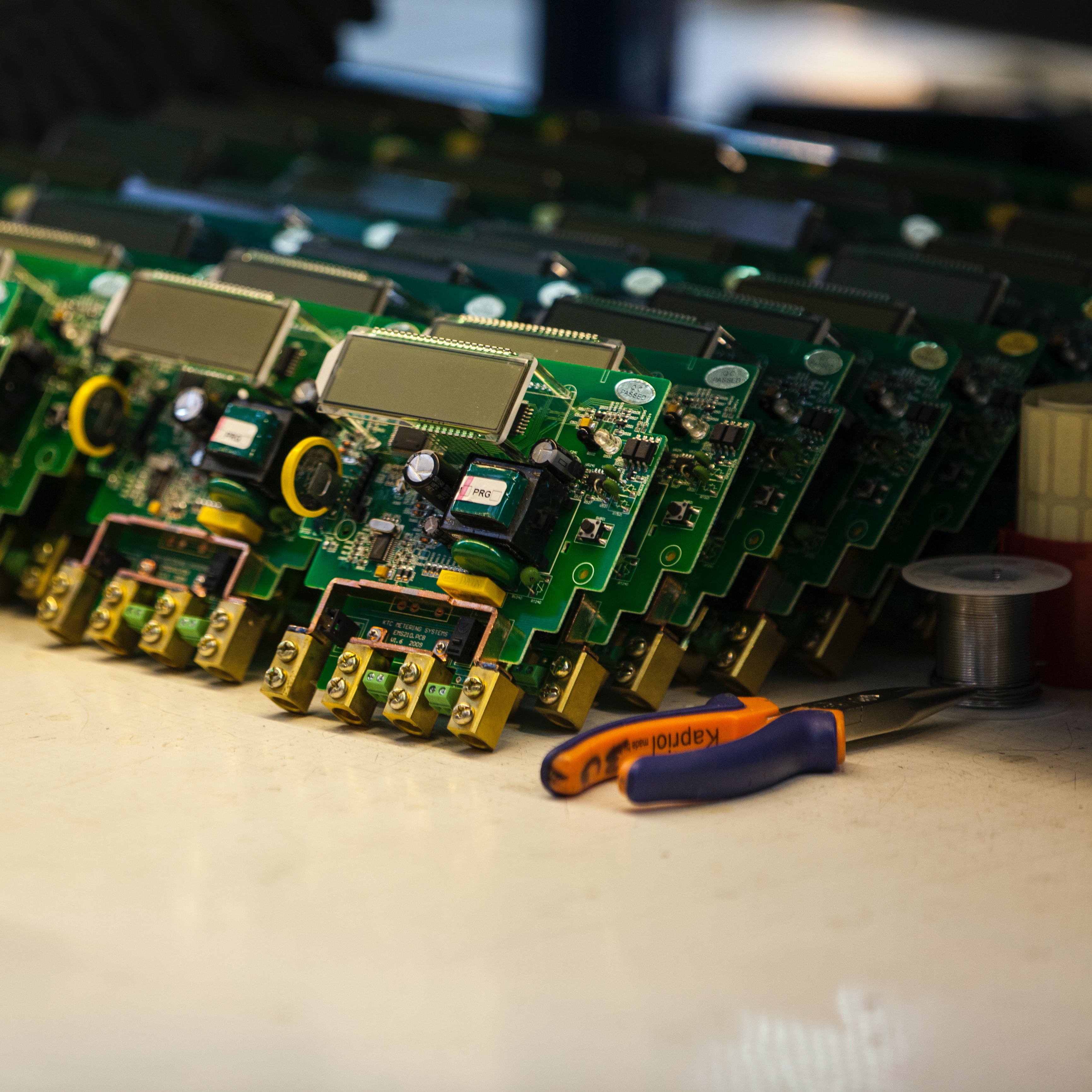

Working alongside the company’s technical team, we began by performing a detailed inventory of each site. This included documenting their current SLA coverages, types of hardware and employee headcounts. We found coverage assigned to hardware that no longer existed. In some locations, network redundancy had been built in but not considered when choosing SLAs.

Next, we sorted the capabilities of the existing hardware. Identified the equipment needed for full network redundancy, then provided hardware or sourced as needed. Knowing the company would be able to capture instant savings, we deployed certified used hardware (averaging 75% off list) and CovrEDGE™ Maintenance, our proprietary warranty and service program.

The result: Edgeium reduced the number of contract termination and renewal dates from 38 to 2. Now a new, customized multi-year contract enables (CovrEDGE) the company to escape OEM-mandated maintenance. We extended the overall hardware lifecycle. All told the company realized a reduction of 57% on their annual maintenance contract costs.

Think about your maintenance contracts. A systematic review to consolidate, streamline, and – most of all — cut waste can simply make good business sense.

Subscribe to our Monthly Newsletter.

✅ Expert IT tips you can actually use

✅ Cost-saving solutions that boost ROI

✅ Straightforward insights — just value

All straight to your inbox.

No spam. No sales pitches. Just better networks.

Environmental sustainability in the IT sector is more critical than ever. At Edgeium, we are committed to reducing e-waste and promoting a circular...

Each year, editors of Britain’s Collins Dictionary select a word of the year; the one word that they believe best epitomizes the global trends and...

OEM (Original Equipment Manufacturer) support contracts—like Cisco SMARTnet—have long been the go-to for IT managers. But with rising costs and rigid...